Proceedings

home home

preface preface

contents contents

authors authors

keywords keywords

copyright copyright

reference reference

©2012 Civil-Comp Ltd

©2012 Civil-Comp Ltd |

|

|

|

K. Utsumi1, T. Kobayashi2, T. Horiuchi2, T. Tanaka3 and Y. Arao3

1Tiger Corporation, Osaka, Japan

2Graduate School of Engineering, 3Faculty of Science and Engineering,

Doshisha University, Kyoto, Japan

Keywords: bottle, vacuum insulation, thermos, inner and outer cylinder, finite element method, shell element.

full paper (pdf) -

reference

A bottle with a vacuum insulation structure is generally called a thermos bottle. It has a dual structure with inner and outer cylinders and the vacuum layer between them. The bottle with this structure maintains heat and cold. They have been found to be useful for many years as a container to carry drinking water.

In recent years, the public concern about environmental issues is growing and the attention to reusable bottles increases. The weight saving of the bottle has been required by dealing the needs of consumers. In reducing the thickness of the bottle for weight saving, the bottle strength decreases. The surface of the bottle is always subjected to pressure loading. As one of the problems that the strength of the bottle is not enough, the outer cylinder of the bottle deformed. It is necessary to clarify the critical strength above which the outer cylinder of the bottle would be deformed in the design. However, the critical strength is not known in the traditional design technique of the know-how only.

The purpose of this study is to investigate the necessary factors for an optimum design of these bottles.

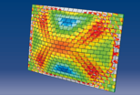

This paper examines the parameters that govern the deformation phenomenon of the outer cylinder of the bottles under pressure loading. The finite element method is used for the simulations. The analytical software is the nonlinear structural analysis LS-DYNA. A double cylinder model is constructed with the shell element, and is subjected to pressure loading both from the side and bottom. The Sus304 material properties are used. For the strength of the bottle, the critical strength of the outer cylinder depends on the shape parameters (the ratios of the height and diameter, and the diameter and thickness of the bottle) and increases with the Young's modulus of the material [1,2]. It is shown that the relationship between the critical strength and the shape parameters is useful for the design of the outer cylinder. This result is demonstrated by conducting experiments with three different bottles.

-

- 1

- S. Kuranishi, "The collection of structural mechanics formulas", Japan Society of Civil Engineers, 400-405, 1986.

- 2

- H. Kobayashi, "How to use JIS series: The structure and design of pressure vessel", Japanese Standards Association, 223-226, 2011.

|